Practical tips for the spray booth

From the professional for professionals: ADLER expert, Walter Streiter, advises how work conditions can be improved by using high quality filters.

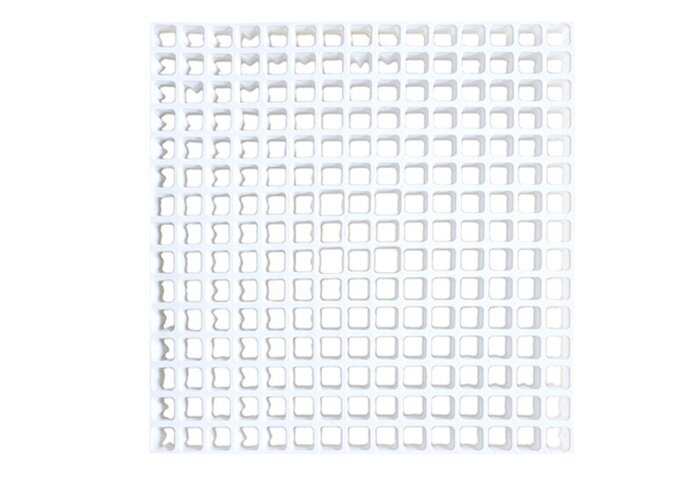

GRATING COVERS MAKE CLEANING EASIER

Spray booths are equipped with exhaust systems, which prevent spray mist from escaping from the work area. The spray booth is therefore nearly always equipped with grating with extraction. ADLER recommends using a plastic grating here, which can simply be fitted over the spray booth’s grating, thus preventing contamination from fine paint spray.

HIGH QUALITY CARDBOARD FILTERS IMPROVE WORK CONDITIONS

For the supply and exhaust air filters we recommend Andreae® cardboard filters with asymmetrically folded, perforated surfaces that are glued on the folds. This forces the air flow charged with paint particles to change direction several times, whereby the particles are held back by the inflowing air. In other words, as soon as the paint particles have set in the settlement tank, they are in a “dead end” outside the air flow.

The cardboard filter is specially designed for horizontal and vertical spray booths. Due to its V-shaped structure and the offset perforation pattern, the overspray is held back and thus achieves a protective effect that is 4-6 times higher than classic types of filter (glass fibre, paper filters). These cardboard filters do not have a very high storage capacity, but instead feature a high service life, which is up to 7 times longer than other types of filter on the market.

Andreae® cardboard folded filters are also fire-retardant.

EARLY FILTER CHANGES REDUCE THE RISK OF FIRE

A pending filter change is usually recognised by the falling suction power. In principle, the filter material should be changed when approx. 2-5 kg of paint solids have been separated per m2 of filter material. A higher level of separated solids increases the risk of fire significantly. The cardboard filter is establishing itself more and more on the market due to its high protective effect.

THE RIGHT PANEL FILTER REDUCES THE CONCENTRATION OF DUST

The filter underneath the cardboard filter is made of a high performance non-woven fabric and is constructed so that it achieves optimum filter performance and dust storage capacity at a low pressure differential. The mat is actively adhesive and provides security against the ingress of dust. There is a panel filter both for solvent-based painting jobs as well as one specially for spray jobs with water-based paints. The blue panel filter, which is made of very fine glass fibres, provides an increased filter action particularly for working with water-based paints.

BREATHING MASK INSTEAD OF BREATHLESS

To protect against aerosols, as a matter of principle a suitable breathing mask must be worn when spraying, as the thresholds for dust and substances damaging to health may be exceeded. Although eyes and airways are frequently protected by appropriate measures, wearing paint overalls especially is often ignored. A big mistake: because the skin is the biggest human organ and absorbs the substances damaging to health – without you noticing it. ADLER therefore recommends a certified disposable overall, which meets the specified requirements and provides protection against dust, liquid chemical sprayers and vapours in the painting booth.

ADLER expert, Walter Streiter, is pleased to answer any questions:

walter.streiter@adler-lacke.com

© by adler-lacke.com