"Windows to a better world": ADLER's surface for PVC profiles by profine

With their proCoverTec premium surfaces, profine are setting new standards for high-quality, durable and sustainable PVC profiles at their production site in Berlin.

3 Oct 2024

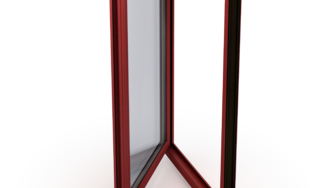

280 million metres: equivalent to approximately seven times around the earth or almost three quarters of the way to the moon – or the annual production of PVC profiles of the international profine Group. With their brands KBE, Kömmerling and Trocal, the corporate group, which is based in Pirmasens, Germany, is one of the world's leading players in the manufacture of PVC profiles for windows, doors and lift & slide elements. These are produced by a workforce of more than 3,400 employees on numerous sites across the world, and sold in over 100 countries. Efficient processes are of course a must with production quantities on this scale, yet the demands in terms of innovative product design, sustainable production and outstanding quality are no less high. Evidence of this can be clearly seen in the premium surfaces of the patented proCoverTec system: profine sells PVC profiles with a high-quality painted surface under this name, and the company is now using the Polycolor Top 2K coating system by ADLER for this product range.

2C in the Vacumat®? No problem!

Since its market launch in 2015, the company has continued to develop proCoverTec – with ambitious goals: a durable and resilient surface, a wide range of colours with good colour stability, environmentally friendly materials and, not least, a reliable coating process using the Vacumat® method, which profine had opted for on their Berlin site. A two-component coating system seemed to be the logical way forward to ensure their high standards, had it not been for one problem: with their limited pot life of just a few hours, 2C coatings are generally considered to be incompatible with the Vacumat® process. However, in the course of discussions with Austrian paint and varnish manufacturer ADLER, a solution emerged which would achieve all their objectives in one fell swoop. Thanks to an innovative hardening technology, the PVC coating Polycolor Top 2K, in a version specially adapted for Vacumat®, can offer a pot life of one full working day – easily long enough for the production of one colour batch. Initial tests under the direction of ADLER Key Account Manager Tim Scharping and technician Marco Ungericht produced results that were more than satisfactory: the high quality of the coating not only ensures that the coating process runs smoothly, but also guarantees maximum efficiency. The pre-fabricated profiles are first cleaned and then activated to give optimum adhesion. They are then coated with Polycolor Top 2K – the high quality and perfect coverage of the paint means that a single coat is sufficient. Throughput time is only around 15 minutes; the coated profiles can then be packaged and prepared for delivery.

Robust and durable

A smooth production process may be important, but the quality of the surface is just as crucial – and here too, all needs are met to perfection with Polycolor Top 2K: the high-quality cross-linking gives the 2C coating the hardness needed to withstand mechanical and chemical stresses and, at the same time, it is elastic enough to remain stable, even when exposed to drastic changes in temperature or humidity. The coated profiles are dirt-repellent and easy to clean, and an innovative anti-heat function prevents them from warping or sticking, even in hot weather. The surface has a uniform matt appearance and shows outstanding colour stability, even after years of UV exposure – and the coating comes in more than 20 standard colours, plus a range of stylish metallic colours. If desired, the windows can also be coated on all sides.

Part of the circular economy

As a company that works with plastics, profine has been pursuing a consistent sustainability strategy since their early days. It goes without saying that they avoid ingredients that are harmful to the environment, such as lead, and make use of recycled materials. As a founding member of the "Rewindo" initiative, profine are committed to the industry-wide recycling of end-of-life PVC windows, and have recently even set up their own recycling plant, allowing 15,000 tonnes of recyclate to be recovered and fed back into the production cycle every year – for example, for the "Reframe" profile series, the manufacturer's first PVC window profile to be made from 100% recycled material. The ADLER coating fits in perfectly with profine's ambitious sustainability concept – the low-VOC, water-based Polycolor Top 2K coating has even been awarded the Cradle to Cradle sustainability seal, confirming its outstanding environmental credentials and recyclability. "Your window to a better world" is one of profine's advertising messages – with their sustainable proCoverTec PVC profiles and ADLER coatings, this German company is coming a good deal closer to making this claim a reality.

ADLER – paint runs through our veins

With 730 employees, ADLER is Austria's leading manufacturer of varnishes, paints and wood preservatives. Founded in 1934 by Johann Berghofer, this family business is now managed by a member of the third generation, Andrea Berghofer. Every year, 21,000 tonnes of paint leave the Schwaz plant and are delivered to customers in more than 30 countries worldwide. ADLER has sales subsidiaries in Germany, Italy, Poland, the Netherlands, Switzerland, the Czech Republic and Slovakia; their sole production site is the ADLER-Werk Lackfabrik in Schwaz, Tyrol (Austria). ADLER was one of the first companies in its sector to be 100% climate-neutral (since 2018). The company has been able to reduce its carbon footprint to a minimum through a wide range of measures. ADLER offsets any unavoidable residual emissions through the purchase of recognised climate protection certificates, thereby helping to finance new climate protection projects

© by adler-lacke.com