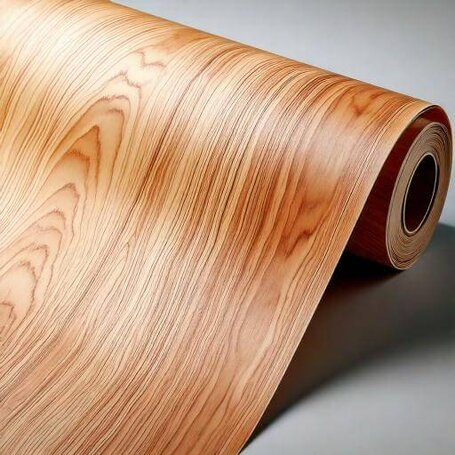

Roll-to-roll coatings by ADLER

ADLER Lacke offers you customised solutions for R2R coating that are precisely tailored to your individual requirements. With more than 120 experts in Research & Development, we offer innovative and high-quality systems that will far exceed your expectations. We are committed to providing the highest standards of customer service – from our first conversation through to successful implementation. With ADLER Lacke, you can be sure of forward-looking technologies, environmentally friendly coatings and great service in a partner-like relationship to give you guidance and support, every step of the way.

ADLER coating systems for "roll-to-roll"

Our sustainable paints and varnishes are tailored to the specific requirements of our customers. As a result, they offer a high degree of flexibility and can be adjusted for use on many different types and thicknesses of material, opening up a wide range of possible applications. Our paints and varnishes offer:

- Outstanding scratch resistance

- Excellent durability

- Maximum elasticity of the paint/varnish film

- Perfect adhesion

- High percentage of renewable raw materials

Roll-to-roll coating solutions for a diverse range of applications

ADLER Lacke brings you tailor-made roll-to-roll coating solutions for a wide range of sectors:

Decor papers and finish foils:

Decor papers are often used in the furniture industry for the finishing of chipboard panels, MDF boards and other substrates. The application of our paints and varnishes not only enhances the aesthetic appearance of items of furniture, it also gives them additional functional properties such as scratch resistance and outstanding durability.

Foil coating:

Here at ADLER, we develop paints and varnishes for plastic and aluminium substrates that meet the highest standards of design and function. In addition to an attractive visual design, our coatings for foils also bring you a number of impressive functional advantages. They offer excellent scratch resistance, a high degree of flexibility and extremely good chemical and mechanical resistance – properties that make surfaces more long-lasting and durable. We are setting new standards in surface finishing with our innovative solutions for the furniture industry.

Edge coating:

Edge coatings play a decisive role in the manufacture of furniture. ADLER offers innovative coatings that have been specially developed to protect edges made of ABS, PVC, PP and other plastics from wear and damage. With their excellent adhesion and natural-looking surfaces, they ensure that your furniture retains its attractive appearance, even after heavy use. Special requirements such as small radii and tight curves make edge painting/varnishing difficult and often result in coats of an uneven thickness or the formation of droplets – ADLER coatings offer an effective solution for this problem, giving you precisely coated, uniform and long-lasting surfaces

RADIATION-CURING COATING SYSTEMS BY ADLER

ADLER's roll-to-roll coatings guarantee maximum flexibility and outstanding surface quality. Our range includes:

- 100% UV paints and varnishes

- Hydro UV paints and varnishes

- EB curing paints and varnishes

- Excimer paints and varnishes

Do you have any questions about our product range? Please contact us for more information >

Efficient production thanks to radiation-curing coating systems

100% UV paints and varnishes: ADLER offers a comprehensive range of products for 100% UV-curing paints and varnishes. This technology enables short drying times, lowers energy consumption and reduces the VOC content (volatile organic compounds), making it especially environmentally friendly. Industrial users can therefore benefit from a high degree of efficiency and first-class quality.

Hydro UV paints and varnishes: With water as the key component of their formulas, hydro UV paints and varnishes bring together sustainability and maximum efficiency. They combine the advantages of water-based systems – low VOC emissions and environmentally friendly for users – with the fast curing of UV technology. ADLER's excimer-compatible hydro-UV paints and varnishes allow you to create especially resilient surfaces. The result: coatings with immediate load-bearing capacity for the most demanding of industrial applications.

Electron beam curing: At ADLER, we use state-of-the-art electron beam curing (EB curing) to cure paints and varnishes quickly, efficiently and without the need for photoinitiators in the roll-to-roll process. This process enables extremely short curing times, high production speeds and outstanding chemical and mechanical resistance – even with thicker coats and intense pigmentation. The coating material is protected thanks to minimal warming of the substrate. With the new EB curing system by Skan, we can simulate production processes in our own in-house facilities, allowing us to optimise our paints and varnishes to meet your requirements with precision. You can therefore benefit from the best possible quality assurance as well as maximum efficiency.

Excimer: ADLER's excimer process facilitates the creation of extremely matt surfaces with especially low gloss levels – ideal for exclusive design and functional applications. Our range includes excimer-compatible hydro UV paints and varnishes which we can tailor to your specific requirements using our modular excimer system by IOT. The use of either LED, gallium or DirectCure means we can realise customised solutions to fulfil your requirements. Find out more about ADLER's excimer coatings here.

Do you have any questions?

Our team of experts are always on hand to provide you with professional and individually tailored support. We take the time to get a proper understanding of your requirements so we can offer you the best possible solution. Instead of one-size-fits-all answers, we believe in giving individually tailored advice and providing fast, solution-oriented support. Why wait? Get in touch with us now – we look forward to hearing from you!

Contact us

© by adler-lacke.com